Over 500 construction professionals dialled in for our Safe Working At Height Week webinar this week. A panel of experts discussed key work at height safety issues and answered questions from the audience.

The panel

Andrew Lack, health, safety and wellbeing manager on Skanska’s 112m-high 20 Ropemaker Street project in London

Gediminas Salkauskas, senior health, safety and wellbeing manager, Sir Robert McAlpine

Brian Parker, head of safety & technical, IPAF

Jason Carlton, head of strategic engagement, PASMA

1. High workforce churn can cause safety difficulties

Andrew Lack: “A big issue is the massive turnover in operative numbers on projects. It’s not uncommon to have a changeover of 50-60% of a project’s workforce within a week. That makes it hard for project teams to impart the right cultures, behaviours, expertise. In turn, that creates a lack of awareness of the work at height issues on a project.”

2. Poor planning remains a major cause of falls from height

Jason Carlton: “The Health and Safety statistics make for grim and depressing reading; they show there is not enough emphasis on planning, competence and avoiding work at height.”

Andrew Lack: “Changes to sequence of works can have a big impact. Where scaffolding was planned as the access method, by that stage of the project there may not be room to erect it, so different access equipment gets used instead. That change can lead to poor behaviours and misuse.”

3. ‘Day to day’ activities are where complacency sets in

Andrew Lack: “High risk activities, like abseiling, we tend to plan incredibly well. But with day-to-day activities, complacency can set in, and we see poor equipment selection.”

Brian Parker: “Our data shows many accidents come from the simple things like not wearing harnesses on boom lifts or standing on guardrails. Globally, over 35% of people killed by falls from platforms weren’t wearing a harness.”

4. Work at height training must be ‘memorable’

Gediminas Salkauskas: “When we raise a safety concern, people often tell me they will deal with that in a toolbox talk. But when I walk around our sites and ask operatives what last week’s toolbox talk was about, not many can remember. Training and inductions can become a real tickbox exercise. We must make sure the content is memorable, that it tells a story which is relevant to people and has real value.”

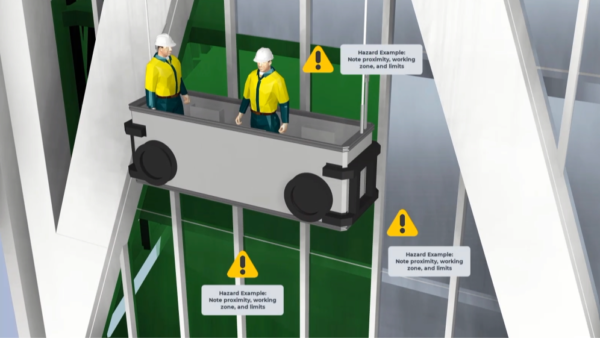

5. Digital tech is making a difference

Andrew Lack: “We’re using software like BIM360, Navisworks, Revizto to take deep dives into high-risk activities. We can create visualisations of the construction sequencing, plan our work, avoid work at height where possible, and where we need to, choose the best access equipment. It also helps with education. We work with a company called Jincom who use VR headsets so that our project teams can spot work at height hazards in a virtual environment first and understand what it’s like working on a high-rise building. We’re just on the cusp in terms of exploiting this technology’s potential."

We’ve now got tier 1 contractors sharing their data with IPAF which means we can learn from everyone’s experiences and share these with the wider industry.”

Brian Parker: “We created the IPAF Epal app during the pandemic, which allows anyone to record their experiences of using powered access platforms, get access to safety information, and check operators’ credentials. We’ve now got tier 1 and tier 2 contractors sharing their data with IPAF – anonymously – which means we can learn from everyone’s experiences and share these with the wider industry.”

Jason Carlton: “The TowerSure app is a gamechanger for tower safety. We issue tens of thousands of PASMA cards every year. To gain a card you need to pass a training course where you have to pass a written and practical test. The delegates are demonstrating a minimum level of competence but the issue for managers is how do they know what good looks like? TowerSure is a simple, easy-to-use mobile app that guides tower users through a consistent and thorough inspection. There are built-in competence checks, so anyone can check if they are a valid cardholder. And the system provides inspection alerts and it allows a safety manager to see all the towers on all the sites and projects without leaving their office."

6. DfMA uptake is reducing work at height

Andrew Lack: “We launched a fall prevention plan across Skanska a few years ago, and through that we’ve done a lot of investigation into modular construction and DfMA. On our Norton Folgate project in London, we’ve used a unitised brick-faced cladding system, which eliminated a huge amount of work at height activity, and saved 40,000 man hours overall. With a traditional build, we would have had a huge scaffolding system, people working on the edge of the building, risks of tools and equipment falling.”

7. Engaging designers early can reduce work at height risks

Jason Carlton: “The first point of the Work At Height Regulations is to avoid work at height. More needs to be done at planning stages to educate designers and eliminate that risk.”

Gediminas Salkauskas: “From Sir Robert McAlpine’s experience, we make a point of having early meetings with designers on our projects. We have successfully challenged – and changed – designs, where we found that they didn’t meet CDM requirements.”

Safe Working At Height Week will return next year during 6-12 November 2023. For email updates, register here.