Gary Walpole sets out steps for the prevention of accidents during roof work at height and warns of a particular emerging safety issue regarding timber battens.

Current Working at Height regulations, though they are fit for purpose, have not eradicated falls from height. Behavioural and cultural change across the industry is crucial to ensure safety on site.

All duty holders should be aware that to comply with regulations and reduce accidents the work should be planned, carried out with the right equipment and materials, and competent contractors chosen. Getting these three things right will result in a reduction in accidents.

Planning works

Clients and building owners need an opportunity to set the tone of the project, to ensure that work at height is properly planned, all hazards have been identified and the risks controlled. Clear and concise guidance is available from the NFRC to help them through this process.

Sometimes, workers assume that a task which only takes a short time to complete is somehow less risky. That can lead to safety being ignored. It is important to plan all roof work, however minor, and execute it in line with Working at Height regulations.

The right materials and equipment

Using the correct equipment and materials is essential to avoid creating additional risk when working at height. One safety critical issue facing those working at height is the volume of imported products falsely stamped with BS 5534. Or it has been dyed a different colour and then marketed and sold as compliant material. This is in part due to the high demand for treated timber, compounded by the shortages created by conflict in Ukraine, Brexit and the Covid-19 pandemic.

The use of inferior battens that do not comply with BS 5534 can potentially cause roof failures and accidents. This risk of accidents increases when the roof battens are being used as an alternative to a roof ladder and are taking the additional live load of the operative installing the roof. HSG33 Health and Safety in Roof Work, from HSE, states that battens must be a minimum size of 50mm x 25mm (maximum span 600mm) or 38mm x 25mm (maximum span 450mm) and meet grading requirements specified in BS 5534: Code of practice for slating and tiling. These are also included in NFRC Technical Bulletin 33, Graded battens for slating and tiling.

Non-compliant battens should not be installed. Ungraded battens may prove weak and vulnerable to failure should the roofer inadvertently walk on these areas whilst covering the roof, potentially putting them at harm. There is also the issue of quality assurance of the whole roof and the impact inferior battens could have on its longevity.

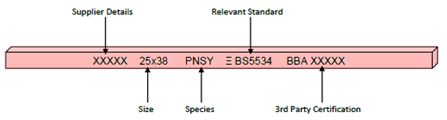

BS 5534 states that all graded roofing battens should be marked with the following:

- Suppliers’ details

- Batten size

- Species

- Relevant Standard, in this case BS 5534

- Third-party certification.

Note: All battens should be individually marked.

NFRC has issued a Safety Alert to highlight the issue to the wider construction sector, working with the assistance of the recently formed industry timber batten working group, which is hosted by NFRC.

Selecting competent contractors

There are still many occurrences of operatives on site who have not proven they have the relevant skills, knowledge, and experience to work at height on roofs. This can mean they do not have an understanding of the relevant hazards. This can arise in particular when those installing or servicing a solar array on a roof, without a roofing background or training, do not have the correct awareness of the dangers of particular fragile roof surfaces, such as roof tiles and slates, or open edges.

Operatives should have the right skillset and the appropriate health and safety training, to ensure that the site (and, afterwards, the finished roof) are safe. Schemes such as NFRC’s RoofCERT accreditation programme will help those employing roofers to make informed decisions and identify operatives who have proven they are skilled and have the correct health and safety knowledge for working at height.

Keep up to date on health and safety

NFRC’s Health and Safety publications are available for everyone in the industry to reference, on topics from preventing falls, to safe handling of solar collectors on roofs, to investigating and reporting accidents.

Gary Walpole is NFRC’s safety, health and environment officer.